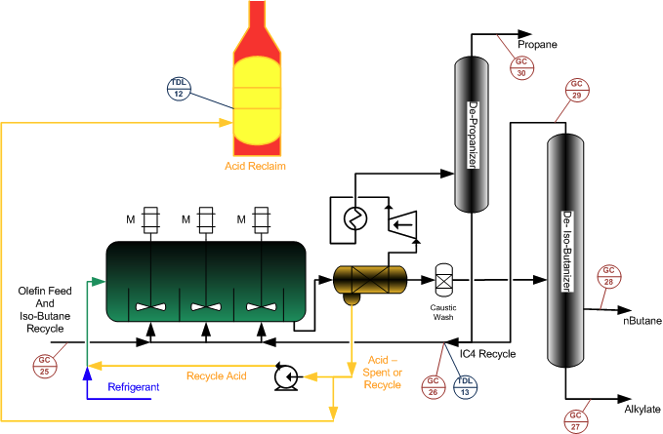

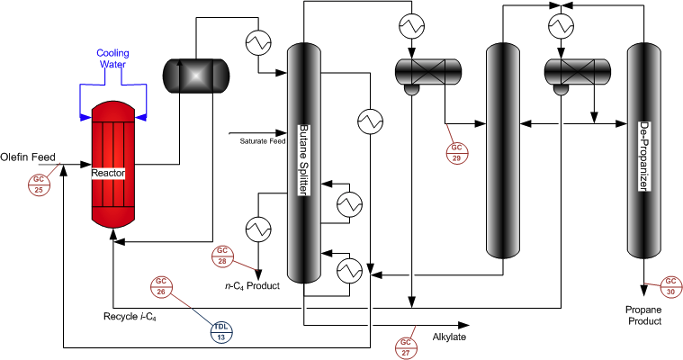

In the refinery, isobutane is alkylated with low-molecular-weight alkenes (primarily a mixture of propylene and butylene) in the presence of a strong acid catalyst, either sulfuric acid or hydrofluoric acid. The process is referred to as a (SAAU) or a , (HFAU). However, oil refinery employees may simply refer to the unit as the Alkyl or Alky unit. The product is called alkylate and is composed of a mixture of high-octane, branched-chain paraffinic hydrocarbons (mostly isopentane and isooctane).

Alkylate is a premium gasoline blending stock because it has exceptional antiknock properties and is clean burning. Alkylate is also a key component of avgas. The octane number of the alkylate depends mainly upon the kind of olefins used and upon operating conditions.

ALKYLATION - SULFURIC

ALKYLATION - HF

TechStar Analyzer Solutions can assist your Alkylation Units with:

- Used to control the proper Iso-Butane to Olefin ratio in the reactor

- Control recycle impurities to maintain the proper Iso-Butane to Olefin ratio in the reactor

- Control RVP when Alkylate is being blended with Gasoline

- Reduce product Impurities

- Reflux control

- Prevent carry-over and loss

- Measuring O2 in furnace

- Combustion Control

- Safety

- Corrosion Protection

SOLUTIONS:

PROCESS GAS CHROMATOGRAPH

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

TUNABLE DIODE LASER SPECTROMETERS

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!