A coker or coker unit is an oil refinery processing unit that converts the residual oil from the vacuum distillation column or the atmospheric distillation column into low molecular weight hydrocarbon gases, naphtha, light and heavy gas oils, and petroleum coke. The process thermally cracks the long chain hydrocarbon molecules in the residual oil feed into shorter chain molecules. The process:

There are three types of cokers used in oil refineries: Delayed coker, Fluid coker and Flexicoker.

There are three types of cokers used in oil refineries: Delayed coker, Fluid coker and Flexicoker.

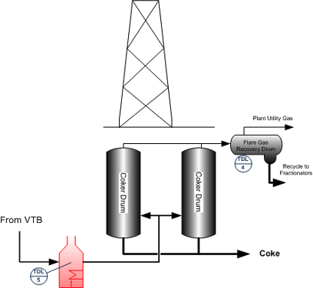

A Delayed Coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke.[1][2][3]

A Fluid Coker, developed by ExxonMobil Research and Engineering Company is an Extension of FCC Fluid Solids Technology Process includes:

- Heavy feed injected into fluidized coke bed with feed rings / nozzles

- Partial combustion of coke in burner and coke circulation provides heat for reaction

- Scrubber preheats feed, separates coke fines, and sets recycle cut point

- Liquid products split in down stream fractionators

- Coke pneumatically conveyed and stored in silos for fuel coke market

Flexicoking process includes:

- Same Liquid Yields as Fluid or Delayed Coking

- Coke Gasified in Integrated Steam Air Gasifier

- Produces Clean CO/H2 Fuel Gas Product Instead of Coke

- FLEXSORB® Hindered Amine Reduces H2S to Low Level Low SOX

- Nitrogen Diluent Reduces BTU Content, But Low NOX

- FLEXIGAS Burned in Refinery or Third Party Furnaces / Boilers

TechStar Analyzer Solutions can assist your Cokers with:

- Maintain O2 below 8% to stay below flammability level

- Combustion Flue Gas Analysis for Safety, Efficiency, Throughput and Emissions Control

SOLUTIONS:

PROCESS GAS CHROMATOGRAPH

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

TUNABLE DIODE LASER SPECTROMETERS

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!