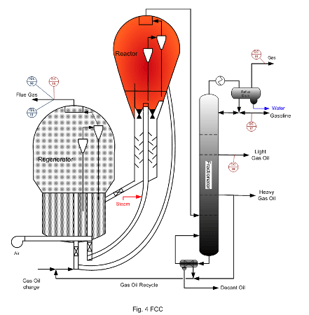

Fluidized-Bed Catalytic Cracking (FCC) is the most important and widely used refinery process for converting low value heavy oils into more valuable gasoline and lighter products. The typical FCC process will convert 75% or more of the heavy oils to gasoline and lighter products. Originally chemical cracking was accomplished by thermally heating the oil to extremely high temperatures but the catalytic process has almost completely replaced thermal cracking. More gasoline having a higher octane value and less heavy oils and unsaturated gas are produced with a catalytic process versus the thermal. The process:

Uses a catalyst to speed up the cracking reaction. Catalysts include zeolite, aluminum hydrosilicate, bauxite and silica-alumina.

Uses a catalyst to speed up the cracking reaction. Catalysts include zeolite, aluminum hydrosilicate, bauxite and silica-alumina.- Fluid catalytic cracking - a hot, fluid catalyst (1000 degrees Fahrenheit / 538 degrees Celsius) cracks heavy gas oil into diesel oils and gasoline.

- Fluid catalytic cracking is similar to hydrocracking, but uses a different catalyst, lower temperatures, higher pressure, and hydrogen gas. It takes heavy oil and cracks it into gasoline and kerosene (jet fuel).

After various hydrocarbons are cracked into smaller hydrocarbons, the products go through another fractional distillation column to separate them.

TechStar Analyzer Solutions can assist your Fluid Cat Crackers with:

- Carbon Balance and Efficiency of Catalyst Regeneration

- FCC unit Mass Balance and Feed Forward information for VRU control

- Monitor Boiling Point analysis for gasoline purity

- Minimize losses of gasoline products into Gas oil

- Control Catalyst regeneration

- Pre-condition regen gas by removing water and catalyst fines

SOLUTIONS:

PROCESS GAS CHROMATOGRAPH

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

TUNABLE DIODE LASER SPECTROMETERS

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!