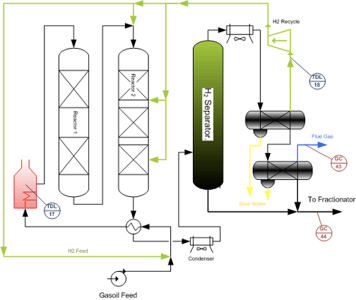

Hydrocrackers break heavy, long chain gas oil molecules into shorter, lighter, more valuable molecules. Carbon bonds are broken, followed by Hydrogen saturation. Typical feedstock is Coker gas oil and gas oils from crude oil distillation. The process includes:

- Feed stock is mixed with Hydrogen, pressurized (2000 psi), and heated (425 C).

- This mixture is sent to a reactor containing a catalyst (typically platinum) where the cracking takes place.

- The hydrogen rich gas is then separated from the cracked product, which is further fractionated.

TechStar Analyzer Solutions can assist your Hydrocrackers with:

- Monitor the impurities in the and BTU in Flue Gas Stream

- Minimize the C3 and lighter components in the product stream

- Combustion Flue Gas Analysis for Safety, Efficiency, Throughput and Emissions Control

- Monitor the Moisture in the HydrogenRecycle Stream

SOLUTIONS:

PROCESS GAS CHROMATOGRAPH

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

Over the past 60 years, GC products from Yokogawa have continued to evolve to meet the ever-changing needs of the process industry. Engineered with reliable electronics and intelligently designed columns & valves, the GC8000 improves ease of maintenance while reducing operating costs.

TUNABLE DIODE LASER SPECTROMETERS

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

Tunable Diode Laser Spectrometers (TDLS) are laser-based gas analyzers that provide real-time optical analysis. TDLS technology offers measurements for process gas, flue gas, impurity analysis, custody transfer and safety, with in-situ and extractive methods supported.

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!

With experience in some of the most complex refineries in the country, there is not much that Don Wyatt, TechStar’s Analyzer Specialist, hasn’t seen. Questions? Pain Points? Complete the form below to discuss your specific process with Don!