WIRELESS PRESSURE SENSOR | SUSHI SENSOR

This product acts as a battery-powered wireless pressure sensor in combination of “XS530 Pressure Measurement Module” and “XS110A Wireless Communication Module”, and it is suitable for Industrial IoT (IIoT) applications. Wireless Pressure Sensor has the function of measuring the gauge pressure of gases and liquids in a piping.

This product designs to realize easy installation for a production site to support direct installation into a piping and wetted material has highly resistant to corrosion.

Supporting Hazardous Location Installation

The XS530 in combination with the XS110A can be installed in Zone 1 areas, such as petrochemical plants, paint plants, steel plants, where flammable gas or vapor may exist.

Long-Distance Communication on License-free Bands

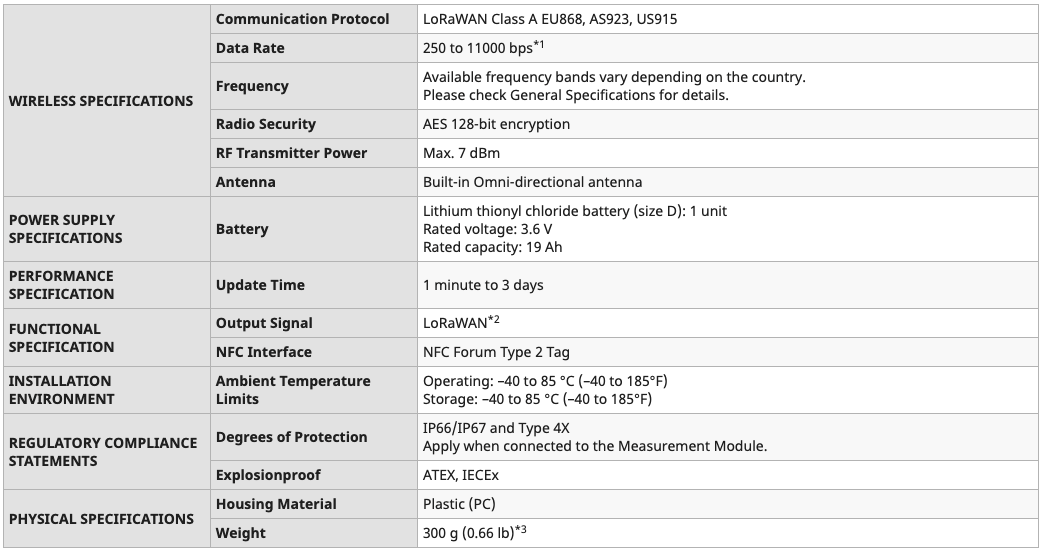

This sensor has adopted LoRaWAN. LoRaWAN has excellent sensitivity reception, good radio interference resistance, and offers a communication distance of 10 km or more in an ideal communication environment. This sensor can be installed this sensor anywhere you want over vast area.

Modular Structure

The module structure enables replacing the battery without removing the XS530 Pressure Measurement Module from the piping, and it makes smooth maintenance of the sensor.

Excellent Environmental Resistance with Battery Powered

The XS110A supplies power to the XS530 from a built-in battery. In combination with XS530, it acts as a battery-powered wireless sensor with the environmental resistance which is required for plant installation. Without any power cabling works, it can be installed everywhere in a plant.

Configuration And Status Monitoring Using Smartphone

Using an Android-based smartphone with NFC (Near Field Communication) interface makes configuration and status monitoring of sensors simple and intuitive.

XS110A Wireless Communication Module

When it comes to traditional machinery protection, showing you how it would work in your facility can be challenging. However, with wireless innovations and compact design of the Sushi Sensor, we can show you exactly how it will integrate with your process machinery. Schedule a demo with our Sushi Specialist, Jeremy Morton!

When it comes to traditional machinery protection, showing you how it would work in your facility can be challenging. However, with wireless innovations and compact design of the Sushi Sensor, we can show you exactly how it will integrate with your process machinery. Schedule a demo with our Sushi Specialist, Jeremy Morton!